Understanding Quartzite Slabs: Geology, Durability, Test Data, and Care

Quartzite slabs offer exceptional strength and striking natural beauty for demanding spaces. At The World of Stone, we stock premium quartzite slabs sourced from leading quarries worldwide. These include popular varieties like Taj Mahal, Cristallo, Four Seasons, and others with soft neutrals or bold veining. This guide covers the basics of quartzite geology, its durability, typical test data, and key care practices. Remember that each quartzite variety and application varies. Factors like specific type, finish, porosity, location, and use influence performance. Always consult professionals, review samples, and request current test data for your project.

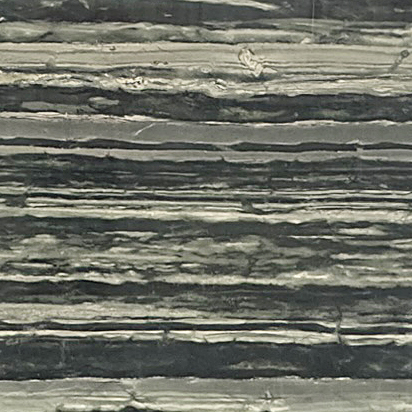

Basic Geology of Quartzite

Quartzite forms as a metamorphic rock. It starts as sandstone—a sedimentary rock made mostly of quartz grains. Intense heat and pressure from tectonic forces recrystallize these grains over millions of years. This fuses the quartz particles into a dense, interlocking mosaic. The primary mineral is quartz (silicon dioxide, SiO₂), often over 90%. Minor impurities like iron oxides or mica add color and subtle patterns. Pure quartzite appears white or light gray. Other minerals create hues of gold, beige, green, or dramatic veining. The recrystallization process eliminates original sedimentary layers, resulting in high hardness and low porosity in quality material. Quartzite often originates from ancient beach or river deposits transformed deep underground. It differs from marble (carbonate-based) and granite (igneous). Commercial quartzite for slabs comes from quarried blocks prized for consistency and visual appeal.

Durability of Quartzite Slabs

Quartzite excels in durability for high-performance applications. Its quartz-rich composition provides superior resistance to scratches, heat, and wear. Quartzite suits busy kitchens, heavy-traffic floors, and even some exterior uses. Quartzite typically scores 7 on the Mohs hardness scale—matching or exceeding granite. This reduces scratches from knives or abrasives. Low porosity in dense varieties limits water absorption and staining. Unlike carbonate stones, quartzite resists acid etching effectively .Quartzite handles high compressive loads and thermal shock well. It performs reliably in freeze-thaw conditions when properly selected. Some varieties show very low absorption, enhancing longevity outdoors or in wet areas. Durability varies by type—true metamorphic quartzite outperforms softer “soft quartzite” or sandstone-like material. Quarry origin, grain size, and finish affect results. Test your specific slab for scratch resistance, stain potential, or exterior demands.

General Test Data for Quartzite

Standards like ASTM guide quartzite testing. ASTM C616 specifies requirements for quartz-based dimension stone, including quartzite. It covers absorption, density, strength, and other properties, with classes based on silica content and performance. Here are typical ranges for common quartzite properties (values vary by variety, density, and test conditions):

- Compressive Strength (ASTM C170): Often 100–350 MPa (14,500–50,750 psi). Many high-quality quartzites range 150–300 MPa. This measures crushing resistance.

- Flexural Strength (Modulus of Rupture, ASTM C99 or C880): Typically 10–25 MPa. This tests bending strength for countertops or cladding.

- Water Absorption (ASTM C97): Usually under 0.1–1.0% by weight in dense varieties. Some premium types stay below 0.2–0.5%.

- Density/Bulk Specific Gravity: Around 2.6–2.8 g/cm³ (higher due to tight quartz interlocking).

- Porosity: Generally low, 0.5–2% in quality material; denser forms approach near-zero effective porosity.

- Abrasion Resistance (ASTM C241): Often high, supporting heavy traffic in floors or pavers.

These figures come from industry data, ASTM standards, and testing reports. Results differ by block, slab, and treatment. Request current test reports or certificates for your chosen quartzite. High-traffic, wet, or exterior uses may require stricter minimums per ASTM C616 guidelines.

Basic Care and Maintenance for Quartzite

Quartzite needs straightforward care to preserve its elegance. Its toughness simplifies routine upkeep compared to softer stones.

- Daily Cleaning: Wipe or mop with a soft cloth using pH-neutral stone cleaner or mild soap in warm water. Avoid harsh abrasives or strong acids.

- Spill Management: Blot spills quickly. Low-porosity quartzite resists most stains, but prompt action prevents rare deep absorption.

- Sealing: Apply a penetrating sealer after installation, especially for porous varieties. Reseal every 1–3 years, or when water no longer beads. Sealing boosts stain resistance further.

- Protection Tips: Use cutting boards and trivets to avoid dulling polish. Place felt pads under furniture. Quartzite handles heat well but protect against extreme direct contact if needed.

- Professional Help: For scratches, stains, or loss of shine, seek expert polishing or honing. Most issues resolve easily with standard stone restoration.

Each quartzite stone and installation differs. Busy kitchens or outdoor features need more frequent sealing than interior walls. Climate, traffic, and finish guide care needs. Follow these basics, but adjust for your specific quartzite and conditions. At The World of Stone, we guide you toward the perfect quartzite for lasting style and strength. Visit our quartzite page for inspiration and explore our selection of durable, one-of-a-kind slabs. Contact us for samples, detailed test data, or expert advice on your next project.