Understanding Onyx Slabs: Geology, Durability, Test Data, and Care

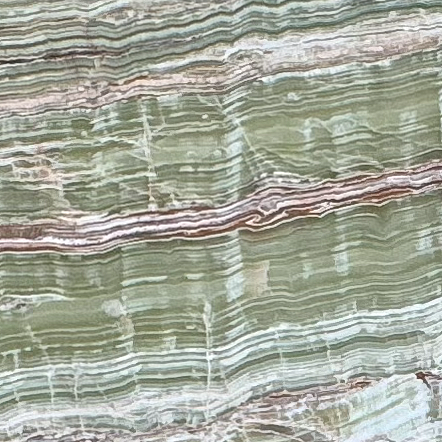

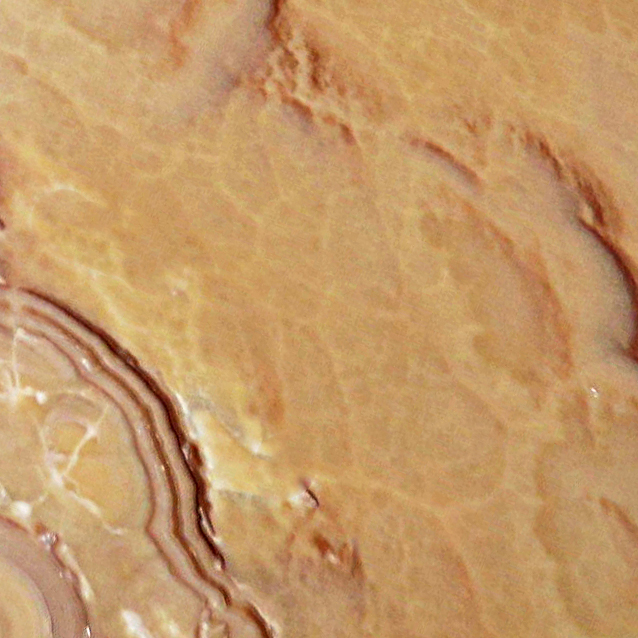

Onyx slabs captivate with their translucent beauty, vibrant colors, and dramatic veining, creating luminous effects in any space. At The World of Stone, we offer premium onyx slabs and tiles sourced from select quarries, featuring varieties such as Black Onyx, Green Onyx, White Onyx Extra, Naranja Onyx, Chanel, and Alabaster-inspired options. These stones excel in backlit applications and luxury finishes. This guide covers the basics of onyx geology, its durability, typical test data, and essential care practices. Important note: The material commonly sold as “onyx” in slabs is not true geological onyx (a cryptocrystalline variety of chalcedony/agate quartz). It is a cryptocrystalline marble or banded calcite stone, often formed as flowstone or cave deposits. True onyx is a silicate-based gemstone, while slab “onyx” is a carbonate rock similar to marble but prized for its translucency. Each variety and application varies. Factors like specific type, finish, porosity, backlighting potential, location, and use affect performance. Always consult professionals, review samples, and obtain current test data for your project.

Basic Geology of Onyx Slabs

Onyx slabs (as used in architecture) form as a sedimentary or semi-sedimentary rock. Calcite-rich groundwater or spring water precipitates calcium carbonate in layers, often in caves, near hot springs, or in fissures. This creates banded, translucent deposits with fine crystal growth.The primary mineral is calcite (calcium carbonate, CaCO₃), sometimes with aragonite. Impurities and mineral banding produce striking colors—green, honey, white, black, or multicolored—and the signature translucency. The cryptocrystalline structure (very fine crystals) allows light to pass through, unlike denser marbles.Unlike true onyx (banded chalcedony quartz, cryptocrystalline silica with hardness 6.5–7), architectural onyx is softer and carbonate-based. It resembles travertine or alabaster in formation but stands out for uniform banding and light transmission. Commercial slabs come from quarried blocks valued for clarity, color consistency, and veining.

Durability of Onyx Slabs

Onyx slabs offer moderate durability suited to elegant, lower-traffic, or protected applications. Their translucency and beauty make them ideal for feature walls, backlit panels, and accents, but they require careful handling.Onyx (calcareous type) typically scores 3 to 4 on the Mohs hardness scale, similar to marble. It scratches more easily than harder stones like quartzite. As a carbonate material, acids etch it readily—calcite reacts to vinegar, citrus, or cleaners, causing dull spots.Porosity varies but often remains low to moderate in quality slabs. Unsealed onyx absorbs liquids, risking stains, though many varieties show low absorption after processing. It handles compressive loads in vertical uses but suits interiors best due to sensitivity.Durability depends on the variety—denser, less porous types perform better. Backlighting highlights beauty but exposes flaws. Quarry origin, resin treatment (if any), and finish influence results. Test your specific slab for etching, staining, or impact in demanding spots.

General Test Data for Onyx Slabs

Standards like ASTM guide testing for calcareous stones, including onyx (often grouped with marble under ASTM C503 or similar). No dedicated ASTM spec exists solely for onyx, but values align with marble/limestone tests.Here are typical ranges for common onyx slab properties (values vary by variety, density, and test conditions; drawn from industry data and reports):

- Compressive Strength (ASTM C170): Often 50–110 MPa (7,250–16,000 psi). Many commercial types range 80–110 MPa. This measures crushing resistance.

- Flexural Strength (Modulus of Rupture, ASTM C99 or C880): Typically 8–20 MPa. This tests bending strength for slabs or cladding.

- Water Absorption (ASTM C97): Usually 0.1–0.5% by weight in dense varieties; some up to 1–2% untreated.

- Density/Bulk Specific Gravity: Around 2.65–2.90 g/cm³ (higher in compact forms).

- Porosity: Generally low, 0.5–5%; processing reduces effective porosity.

- Abrasion Resistance (ASTM C241): Moderate; values support light to medium traffic when honed or polished.

These figures come from industry sources, testing, and standards for similar calcareous stones. Results differ by block, slab, and treatment (e.g., resin filling). Request current test reports or certificates for your chosen onyx. High-traffic or exterior uses may need denser selections meeting stricter minima.

Basic Care and Maintenance for Onyx Slabs

Onyx requires gentle care to preserve its translucent glow and prevent damage. Thoughtful habits extend its life in luxury settings.

- Daily Cleaning: Wipe with a soft cloth and pH-neutral stone cleaner or mild soap in warm water. Avoid acidic cleaners like vinegar, lemon, or harsh chemicals—they etch the carbonate surface.

- Spill Management: Blot spills immediately. Acids etch quickly; prompt action prevents permanent marks.

- Sealing: Apply a penetrating sealer after installation. Reseal every 6–12 months, or when water stops beading. Sealing reduces staining but does not stop acid etching.

- Protection Tips: Use coasters, trivets, and mats. Avoid direct heat, abrasives, or heavy impacts. Place felt pads under objects to prevent scratches.

- Professional Help: For etching, stains, or dullness, consult experts. Light polishing restores shine; severe issues may need honing or refinishing.

Each onyx stone and installation differs. Backlit features or wet areas need extra protection compared to dry walls. Climate, traffic, and finish guide care. Follow these basics, but adjust for your specific onyx and conditions. At The World of Stone, we help you select the ideal onyx for stunning, luminous designs. Visit our onyx slabs page in Los Angeles for inspiration and explore our collection of translucent beauties like Green Onyx, Black Onyx, and more. Contact us for samples, detailed test data, or expert guidance on your next project.