Understanding Marble Slabs: Geology, Durability, Test Data, and Care

Marble slabs add timeless elegance to homes and commercial spaces. At The World of Stone, we offer a wide selection of premium marble slabs. This guide explains the basics of marble geology, its durability, typical test data, and essential care practices. Remember, each marble variety and every application differs. Factors like specific type, finish, location, and use affect performance. Always consult professionals for your project.

Basic Geology of Marble

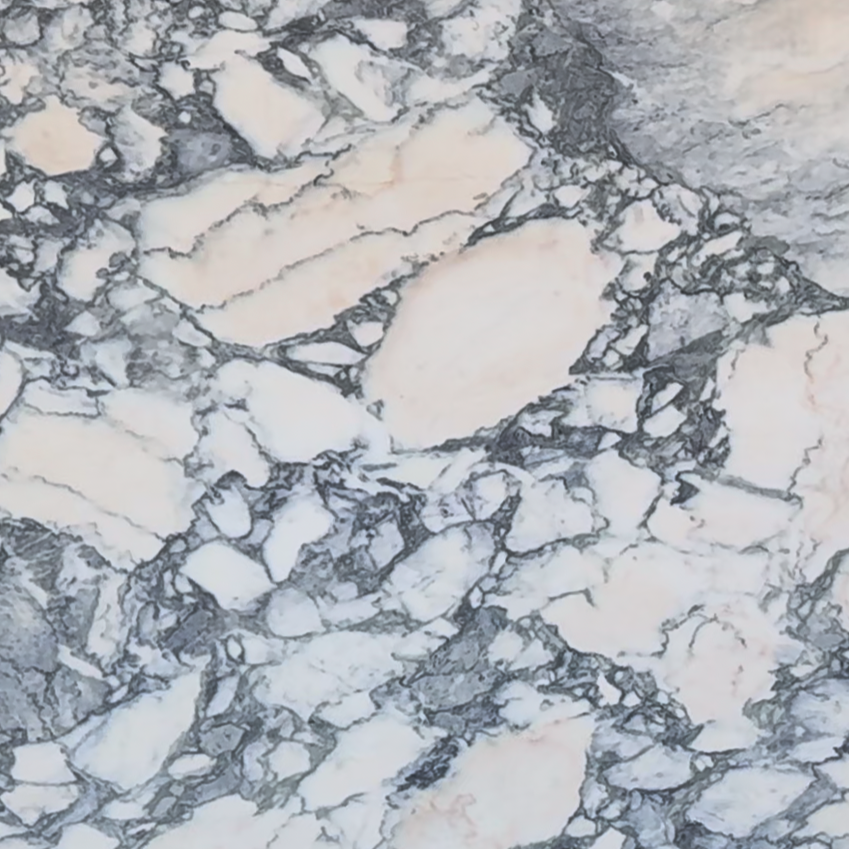

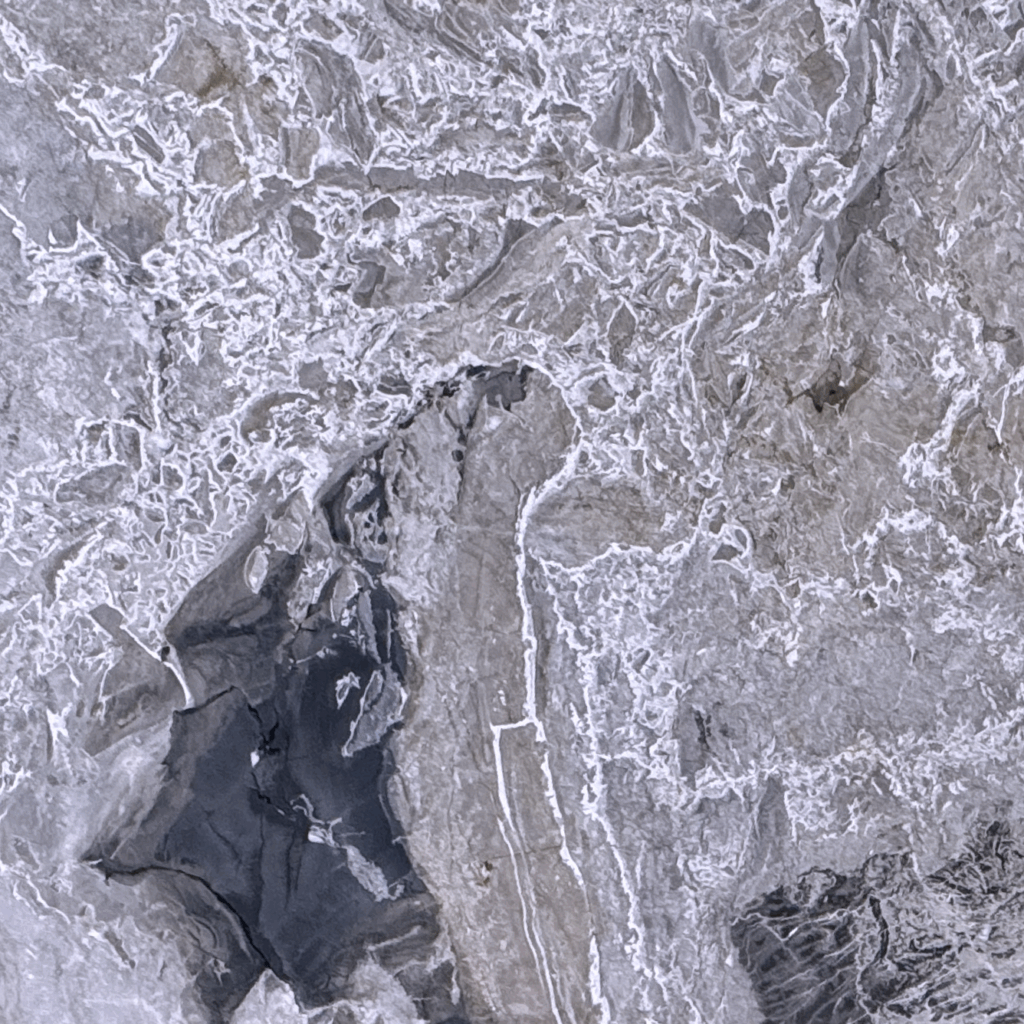

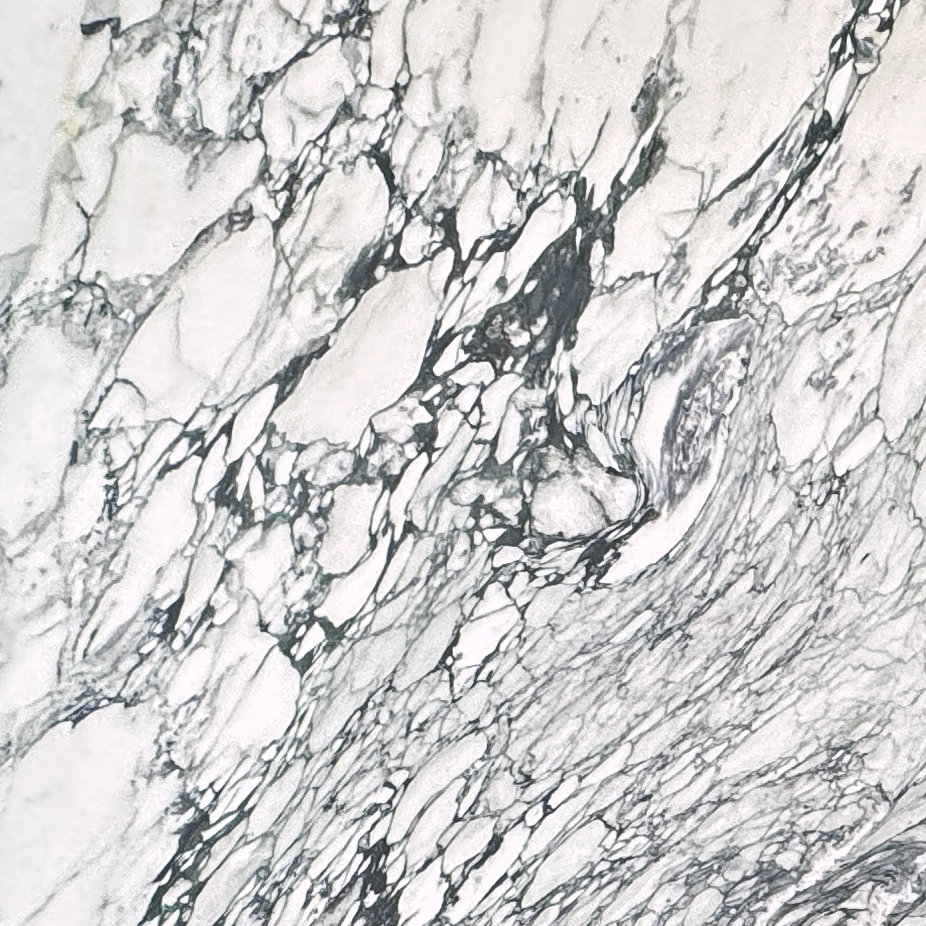

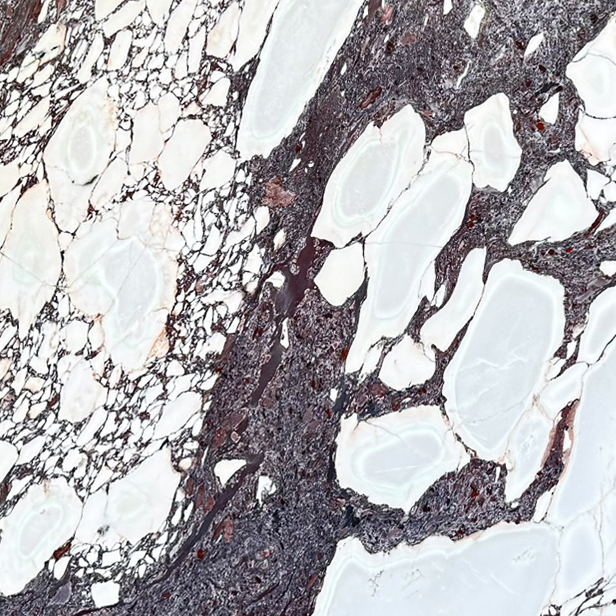

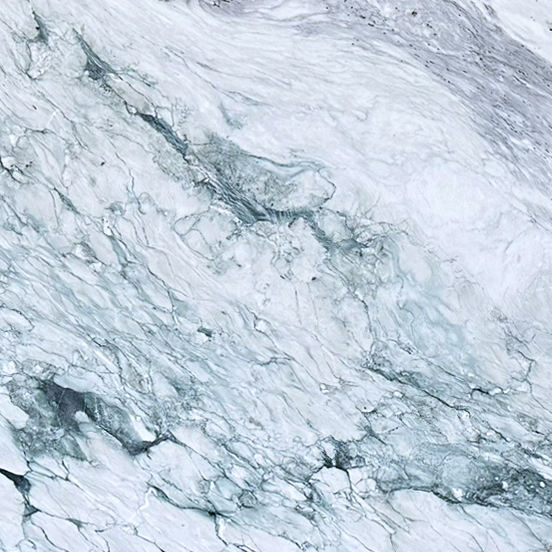

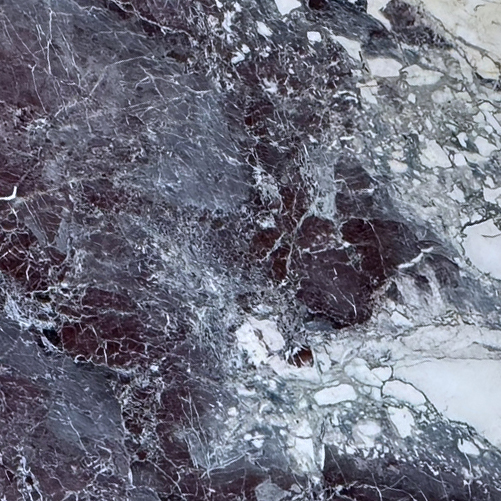

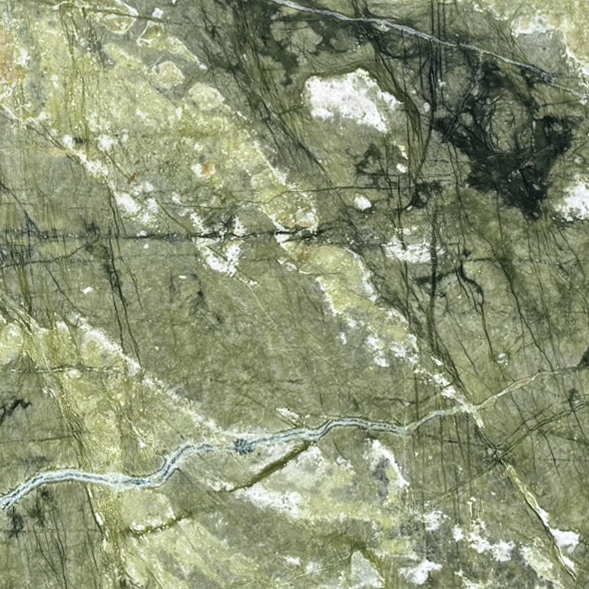

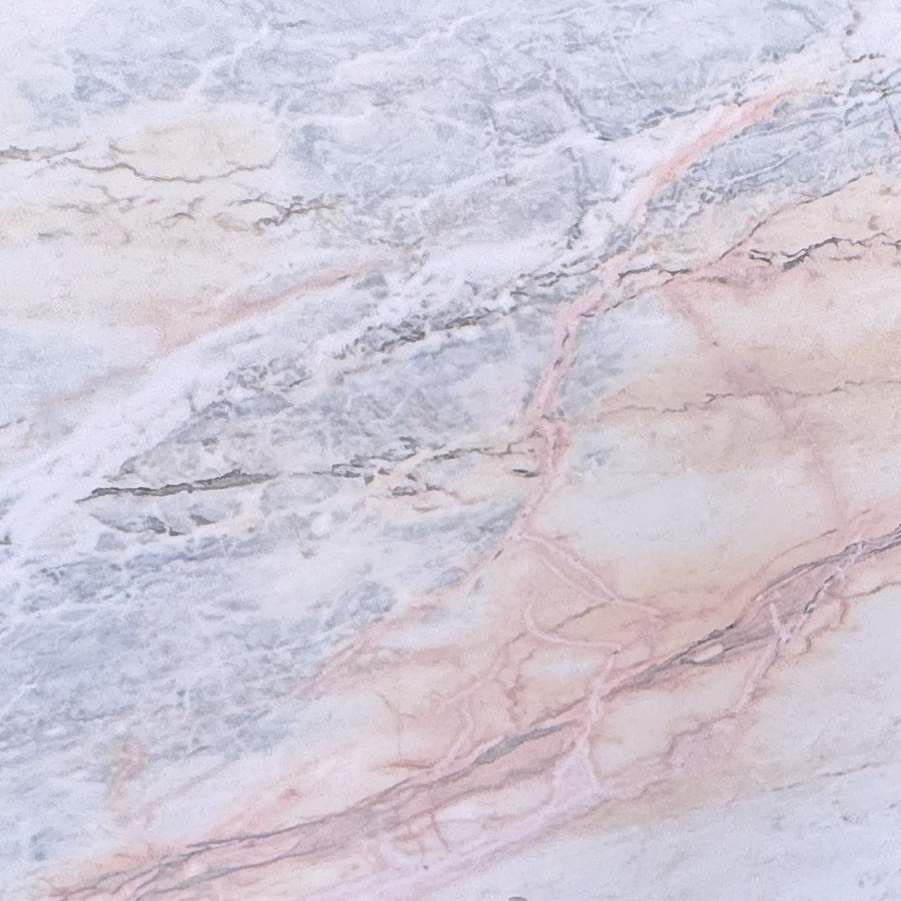

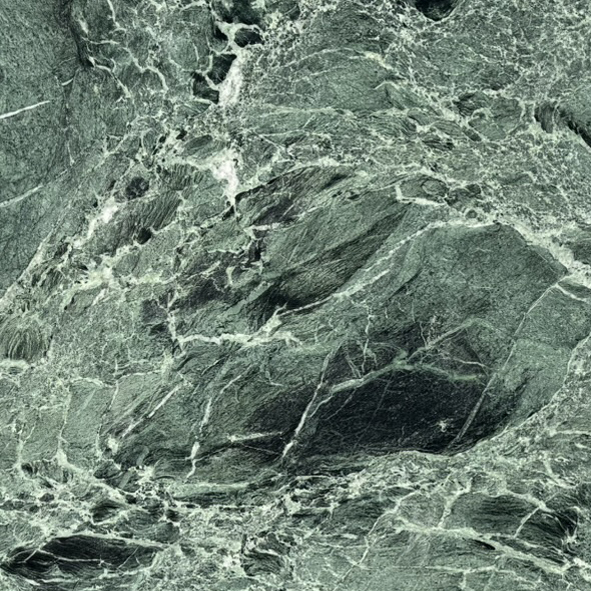

Marble forms as a metamorphic rock. It starts as limestone or dolostone—sedimentary rocks rich in carbonate minerals. Deep in the Earth, intense heat and pressure recrystallize these minerals over millions of years. This process creates marble’s signature crystalline structure. The main mineral in most marble is calcite (calcium carbonate, CaCO₃). Some varieties contain dolomite (CaMg(CO₃)₂). Impurities like clay, iron oxides, or graphite produce the beautiful veining, colors, and patterns. Pure limestone yields white marble. Other minerals create gray, pink, green, or black tones. This metamorphic change eliminates original sedimentary features, like fossils. It results in a dense, interlocking crystal mosaic. This structure allows marble to take a high polish and show natural beauty. Marble often forms at convergent plate boundaries through regional metamorphism. Contact metamorphism near hot magma bodies can also create it.

Durability of Marble Slabs

Marble offers good durability for many interior uses. Its crystalline structure provides strength and elegance. However, marble ranks softer than granite or quartzite on the Mohs hardness scale. Marble typically scores 3 to 4 on the Mohs scale. This makes it prone to scratches from harder materials. Acidic substances etch marble easily because calcite reacts to acids. Etching creates dull spots that sealing does not fully prevent. Marble shows moderate porosity in most varieties. It absorbs liquids if unsealed, which can lead to stains. Proper sealing reduces this risk. Marble handles compressive loads well in vertical applications like walls. Horizontal uses, such as countertops or floors, require careful selection and maintenance. Durability varies by marble type. Calcite-based marble reacts more to acids than dolomitic types. Each stone’s origin, mineral content, and quarrying affect its performance. Test samples from your specific batch for best results.

General Test Data for Marble

Industry standards like ASTM guide marble testing. ASTM C503 sets specifications for marble dimension stone. It includes requirements for absorption, density, strength, and abrasion. Here are typical ranges for common marble properties (values vary by specific variety and testing conditions):

- Compressive Strength (ASTM C170): Often 800–1,500 kg/cm² (or 70–140 MPa). Many commercial marbles fall around 1,000–1,200 kg/cm². This measures resistance to crushing forces.

- Flexural Strength (Modulus of Rupture, ASTM C880 or C99): Typically 7–15 MPa. This indicates bending resistance, important for countertops or stairs.

- Water Absorption (ASTM C97): Usually under 0.2–0.5% for dense varieties. Higher absorption appears in some types.

- Density/Bulk Specific Gravity: Around 2.6–2.7 g/cm³.

- Abrasion Resistance (ASTM C241): Often 10–50 Ha (abrasion index). Higher values mean better wear resistance for floors.

- Porosity: Generally low, 0.4–2% in quality marble.

These figures come from industry data and standards. Actual test results differ by quarry, block, and slab. Always request current test reports or certificates for your chosen marble. Applications in high-traffic or wet areas may need higher minimum values per ASTM guidelines.

Basic Care and Maintenance for Marble

Marble requires thoughtful care to stay beautiful. Daily habits and regular protection extend its life.

Professional Help: For etching, stains, or dullness, consult experts. Polishing powders restore shine for light issues. Deep problems may need honing or refinishing.

Daily Cleaning: Wipe surfaces with a soft cloth and pH-neutral stone cleaner or mild soap in warm water. Avoid acidic cleaners like vinegar, lemon, or harsh chemicals—they etch marble.

Spill Management: Blot spills immediately. Acids (wine, citrus, coffee) etch quickly. Do not rub; blotting prevents spreading.

Sealing: Apply a penetrating sealer soon after installation. Reseal every 6–12 months, or as needed. Test by sprinkling water—if it beads, the seal holds. Sealing reduces staining but does not stop etching from acids. Each application is different so it is wise to consult sealer manufactures to customize a sealing and maintenance plan customized to your needs.

Protection Tips: Use coasters, trivets, and cutting boards. Avoid direct heat or abrasive pads. Place felt pads under furniture to prevent scratches.

Each marble stone and installation varies. High-traffic floors or kitchens demand more frequent care than walls. Environmental factors like humidity affect performance. Follow these basics, but tailor maintenance to your specific marble and use. At The World of Stone, we help you select the right marble for your needs. Browse our marble slabs and tiles page for inspiration. Contact us for samples, test data, or expert advice on your project.